Following the KAIZEN™ principle of continuous improvement through minimising inefficiencies allows us to build better, at a better price.

At Ecopod, we pride ourselves on the prompt production of high-quality and cost-effective homes. The feedback from customers and colleagues who visit our yard is that our quality and value offered stands out as better than our competition. And we’re able to consistently demonstrate these results with a typical build turnaround of just five weeks.

So, how do we hit the top three performance objectives of high quality, fast turnaround, and a lean price? It comes down to our application of the KAIZEN™ quality manufacturing mindset our Ecopod team have adopted.

The KAIZEN approach is a total manufacturing philosophy, derived from the Toyota Production System (TPS). Toyota had to run a lean operation to survive the socio-economic aftermath of WWII and other global challenges. One of the many insights the philosophy offers is to adopt a mindset of continuous improvement in pursuit of excellence through minimising waste (inefficiencies). It defines seven different types of waste, namely: Transport, Inventory, Movement (of people), Waiting, Overproduction, Overprocessing, and Defects. Each of these waste streams is common, as well as measurable. The KAIZEN approach asks us to first measure the current state, then set objectives to reduce the waste, and track progress towards eliminating the waste from the process.

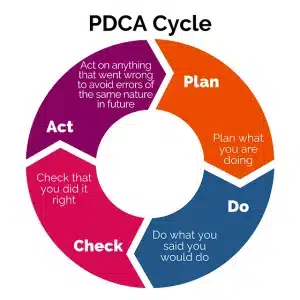

Plan, Do, Check, Act

The process of iteration follows a regular pattern, abbreviated to PDCA, which stands for Plan, Do, Check, Act. This scientific problem-solving method underpins everything we do, so we’re constantly reassessing our methods to make sure they’re achieving our objectives to be New Zealand’s leading manufacturer of high-quality buildings.

The core focus of the KAIZEN mindset is not on profitability, although that’s of course a measurable outcome. Rather, it’s on adding value to the customer, which takes on several meanings in a KAIZEN context. To understand how we create value, we focus on making work easier, better, faster and better value, in that order, as Dr Shigeo Shingo, Toyota’s legendary industrial engineer, famously stated. That also applies to the people working in the company, who at various parts of the process are considered customers, as they receive the outputs from the previous process. So, at each step in the building of a pod, people are challenged to consider what can be done to make their work more valuable and more fulfilling.

A commitment to learn and improve

The Director of Kaizen Institute New Zealand, Peet Wiid, has been mentoring the Ecopod team in learning and applying the foundational KAIZEN principles. Here’s what he has to say about our journey working together:

‘The highly engaged team at Ecopod is an excellent example of how commitment to the ongoing improvement of people and process can enable a clearly defined business strategy. Their latest process improvements are always obvious when I arrive on my regular visits, showcased and celebrated with confident humility, and based on respect for people.

‘It is highly fulfilling to see the frontline people and management working together to find ongoing solutions for their manufacturing and installation methods and techniques. However, this creative team also realised that big gains in waste reduction can be made during the preceding designing phase.

‘As I said to the senior management at Ecopod, “The sky is the limit for your business because you know how to create customer value and how to eliminate inefficiencies through your commitment to learn and improve.”’

Spurred by this, we look forward to tackling more challenges every day, making our jobs more fulfilling and our work more valuable to our customers.

Delivering on time and on budget

In the building industry at large, processes are notoriously prone to delays, defects and budget blowouts, all of which we at Ecopod aim to eliminate through KAIZEN methods. We’re always thinking about our next customer, which, for our builders, can be the painter or electrician, and asking ourselves: what are their expectations of the product they receive? This simple question is one mindset shift that helps us to deliver in full, on time, and on budget more than ever before.

If you’re interested in finding out more about our KAIZEN systems, feel free to get in touch and we can show you our 250+ step quality checklist and our pod pathway diagram, and invite you to our factory to see how we’re putting lean manufacturing principles into action.

Find out more

Chat with our team to find out more about the range of Ecopod designs and custom options.